Easylabel features a GS1 barcode wizard to help guide you through creation of GS1-128, GS1 databar and GS1 datamatrix barcodes. The wizard prompts you for the required field information and then builds the barcode accordingly. You even have the opportunity to create barcodes with multiple application identifiers.

Below you will find samples of the most commonly used barcodes and their uses. If you require assistance with barcode creation in Easylabel please complete our product support form or call 01642 490121 and one of our engineers will be able to help you through the process.

The correct type of barcode must be chosen before including it on the packaging for your products. Below we will explain the different types of product and the barcodes used for each. Weyfringe have also produced a handy guide for barcode mistakes to avoid.

To request a FREE virtual or on-site product demonstration for any of our barcode and labelling machinery and software please click the button below

Barcodes for consumer units

Barcodes used for consumer units are UCC/EAN-8, UCC/EAN-13, UPC-A and UPC-E barcodes. Most UK retailers will use UCC/EAN-13 barcodes on consumer products and UCC/EAN-8 barcodes for very small consumer products. UPC-A and UPC-E are the american equivalent of UCC/EAN-13 and UCC/EAN-8 barcodes and occupy the same area, they can be used in the UK and elsewhere with no problem.

Basic Rules for Consumer Barcode Labelling

|

UCC/EAN-8

UCC/EAN-13

UPC-A

UPC-E

Barcodes for traded units (outer cases etc.)

Barcodes for warehousing and distribution uses are UCC/EAN-13, UPC-A, ITF-14 and GS1-128 barcodes. The type of barcode used depends on the type of outercase, packaging material and type of information required by trading partners. As traded items will often be sold at a wholesale point of sale it is vitally important that the barcodes on the consumer units within cannot be scanned at this point of sale. Some products such as large multi-packs, white goods or furniture are both traded units and consumer units. In this instance the item number is the same for both uses and a UCC/EAN-13 or UPC-A barcode is required for the retail point of sale.

Basic Rules for Traded Unit Barcode Labelling

|

UCC/EAN-13

UPC-A

ITF-14

GS1-128

Barcodes for logistics units (pallets etc.)

Barcodes for logistics units are GS1-128 barcodes including Serial Shipping Container Code (SSCC). Each shipping container, transport unit or pallet is identified with a unique SSCC. These barcodes, together with the application identifier standards, enable companies to provide additional information about the product alongside the Global Traded Item Number (GTIN) for the product itself. These barcodes cannot be scanned at the retail point of sale.

Basic Rules for Logistics Barcode Labelling

|

GS1-128

QR Codes

Quick Response (QR) codes have grown in popularity outside of product identification due to their ability to easily carry URLs and the multitude of reader apps designed for mobile devices. Many companies now use QR codes as a marketing tool to promote their website, new products etc. Originally designed to help identify parts within large scale manufacturing plants users soon realised the potential applications outside of its intended use. However when applied to industry the uses of QR codes are almost limitless, some industrial examples of QR code uses are: Facilities management - critical schematics and specifications for specific locations (wiring, plumbing, alarms etc.) which can be accessed by maintenance personnel or contractors, Latest revision record keeping - provide up to date records on maintenance, repair, inventory etc. Instructions & Procedures - Provide work instruction or procedures for specific equipment operation etc.

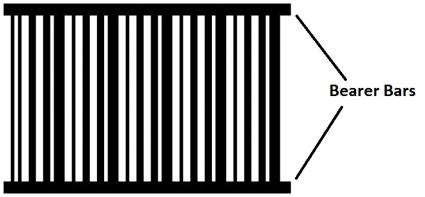

Bearer Bars

Using bearer bars helps ensure accurate production of your barcodes, they are not mandatory but strongly recommended to highlight barcode printing problems. When barcodes are printed on demand with the bars vertical (picket fence orientation) any missing printhead elements will appear as white gaps in the bearer bars above/below the barcode, allowing an operator to clearly see if barcode printing issues occur.